Products

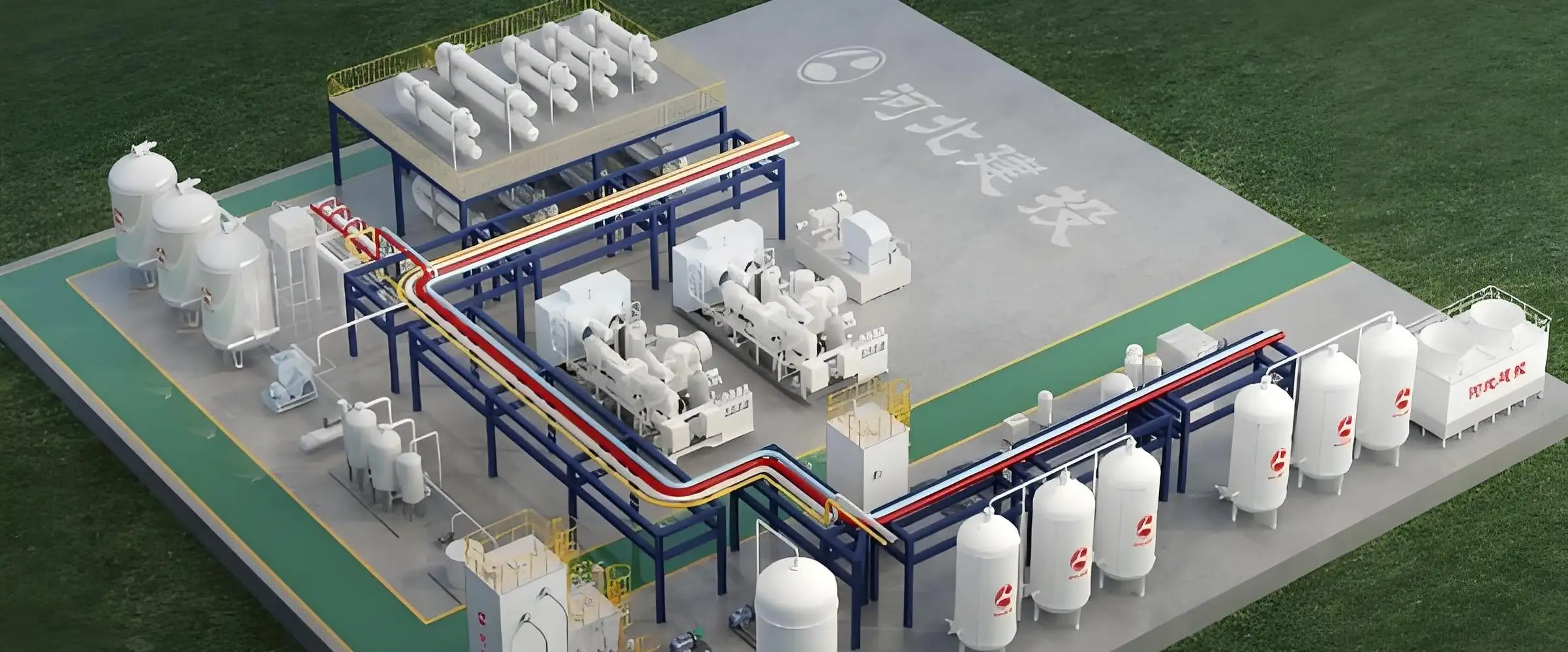

Air Separation unit (ASU)

Capacity Range:Our equipment offers a wide capacity spectrum, ranging from 80 Nm³/h to 120,000 Nm³/h.

Product Portfolio:We provide air separation units in large, medium, and small scales, along with liquid plants, liquefaction plants, high – purity nitrogen generators, and rich oxygen units.

Application Fields: Metallurgy, Steel, Chemical Industry (Petrochemical Industry, Coal Chemical Industry), Machinery, Environmental, Electronics, Pharmaceutical, Glass, Tires, Nuclear Industry, Aerospace, Polysilicon, Energy, etc.

Applications of Liquid Air Energy Storage

Utilize LNG cold energy (-162°C) to precool compressor inlet air, reducing compression power consumption.Enhance air liquefaction efficiency by combining cold energy from LAES’s cold storage unit (stored during discharge phase) with LNG cold energy.

Bio LNG

Production Feasibility:Bio LNG, a cryogenic renewable bio-fuel, can be manufactured wherever anaerobic digestion (AD) and subsequent liquefaction upgrading are possible. The anaerobic digestion and Bio LNG production processes are vital in addressing clean energy production, environmental protection, and waste management issues.

Multiple Applications:Biogas is purified and liquefied into Bio LNG, which is almost 100% methane. As a renewable energy, the liquefaction of biogas boosts its economic value. Bio LNG (also known as liquefied bio-methane) is especially suitable for energy – intensive manufacturing and industrial companies, as well as the transportation industry.

Biologicals-NAD+

Nicotinamide adenine dinucleotide (NAD+)is one of the most important coenzyme your body and is present in all your cells.It is known to be involved in over 500 different reactions that keep cells in good health. Think of NAD+ as the electricity that charges the batteries of your cells(called mitochondria). All cells have a large amounts of mitochondria and each requires NAD+ for energy to function at optimal levels.

Hyperbaric Oxygen Chamber

A hyperbaric oxygen chamber is a specialized medical device used for hyperbaric oxygen therapy (HBOT), a treatment that involves breathing pure oxygen in a pressurized environment. The increased pressure allows the body to absorb significantly more oxygen than usual, which can promote healing and treat various medical conditions.

LNG Cold Energy Recovery ASU

LNG Cold Energy Recovery Overview

Liquefied Natural Gas (LNG) releases significant low-temperature cold energy (-162°C, ~830 kJ/kg) during classification. Traditional vaporization methods waste this energy, while cold energy recovery technologies can improve energy utilization by 20%-40% and reduce thermal pollution.

Methanol Hydrogen Production

Begin with a Hydrogen Production Plant

In the low-carbon era, it all starts with a hydrogen production plant.Low-carbon is the essence of sustainable development. We are committed to providing high-quality technical services to a wide range of customers in the field of hydrogen energy application technologies.

Natural Gas Treatment and Liquefaction (LNG) Process

Capacity Range:Our facilities can handle gas volumes spanning from 1×10⁴ Nm³/d (equivalent to 7 TPD) to a substantial 1000×10⁴ Nm³/d (or 2.5 MTA).

Application fields:Pipeline Gas, Coal Bed Gas (Coal Bed Methane), Coke Oven Gas, Shale Gas, Bio Gas, Coal Gas Purification and Liquefaction, BOG Recovery and Liquefaction, LNG Vaporization Station, LNG Filling Station.